As a professional manufacturer in China with 10 years of experience in open-ear headphones for global B2B export, we at ALOVA often hear these questions:

- “Why is the cost so high just for changing the color?”

- “Why do you require a minimum order quantity for custom colors?”

We want to show you the real costs and the professional process behind this.

The Real Cost of Custom Color

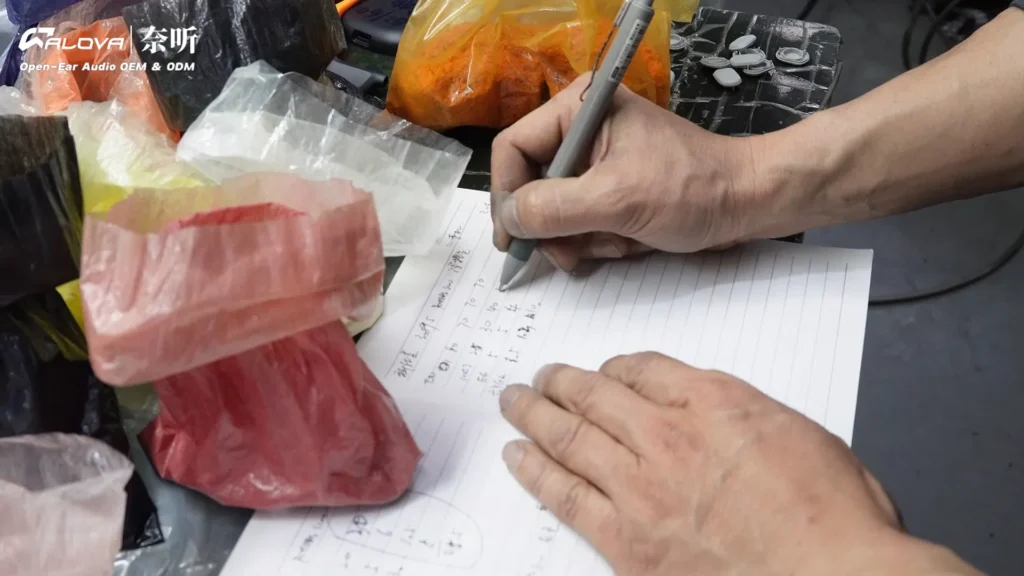

Custom color is more than just changing a shade. It is a detailed process. It takes both time and skill.

Here is how it works:

1. Pick the right plastic base.

2. Calculate the pigment mix from the Pantone code.

3. Weigh the color powder to ±0.01 g.

4. Pre-mix for even blending.

5. Mix the color with the plastic resin.

6. Run the mix through the injection molding machine.

7. Make a sample and check the color.

8. Adjust and repeat until it matches.

For black or white, we need 3–4 rounds.

That takes about 60–90 minutes.

For a custom color, we need 5–10 rounds.

Each round takes 40–60 minutes plus 20–30 minutes for cleaning.

Total time is 2–6 hours.

This time uses both machine hours and skilled labor.

That is why sampling costs more than just the plastic.

Why MOQ Is High for Custom Colors

After color sampling, we need a minimum order quantity (MOQ).

This keeps the process cost-effective.

Here is why:

- A production machine can make 2,400 earphone shells per day.

- Changing colors often causes cleaning and downtime.

- Small runs raise material and labor costs a lot.

- A larger run spreads these costs over more parts.

So, a high MOQ helps keep the price fair and the delivery on time.

This is how most factories work.

Conclusion

Custom color is not just a color switch. It is a precise process.

It uses skilled work and machine time.

MOQ makes this work cost-efficient.

At ALOVA, we help our partners find the right balance.

Contact us to learn more about custom audio solutions.