What is a Pogo Pin? The “Energy Hub” of TWS Earphones

The Pogo pin, often called a spring-loaded pin or probe, may be small, but it shoulders the critical responsibility of being the “energy hub” in TWS earphones.

Simply put, it is the bridge connecting the earphones to the charging case, responsible for transmitting power to ensure the earphones are always fully charged.

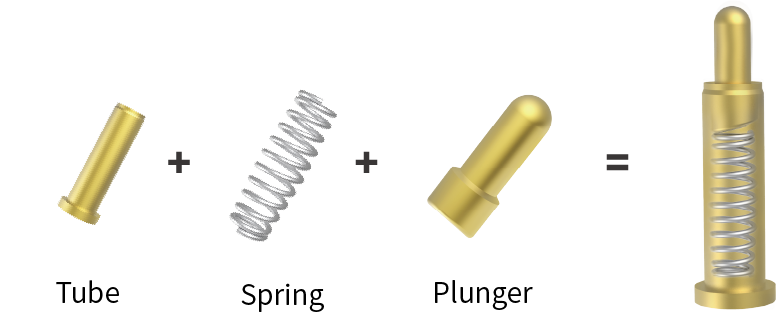

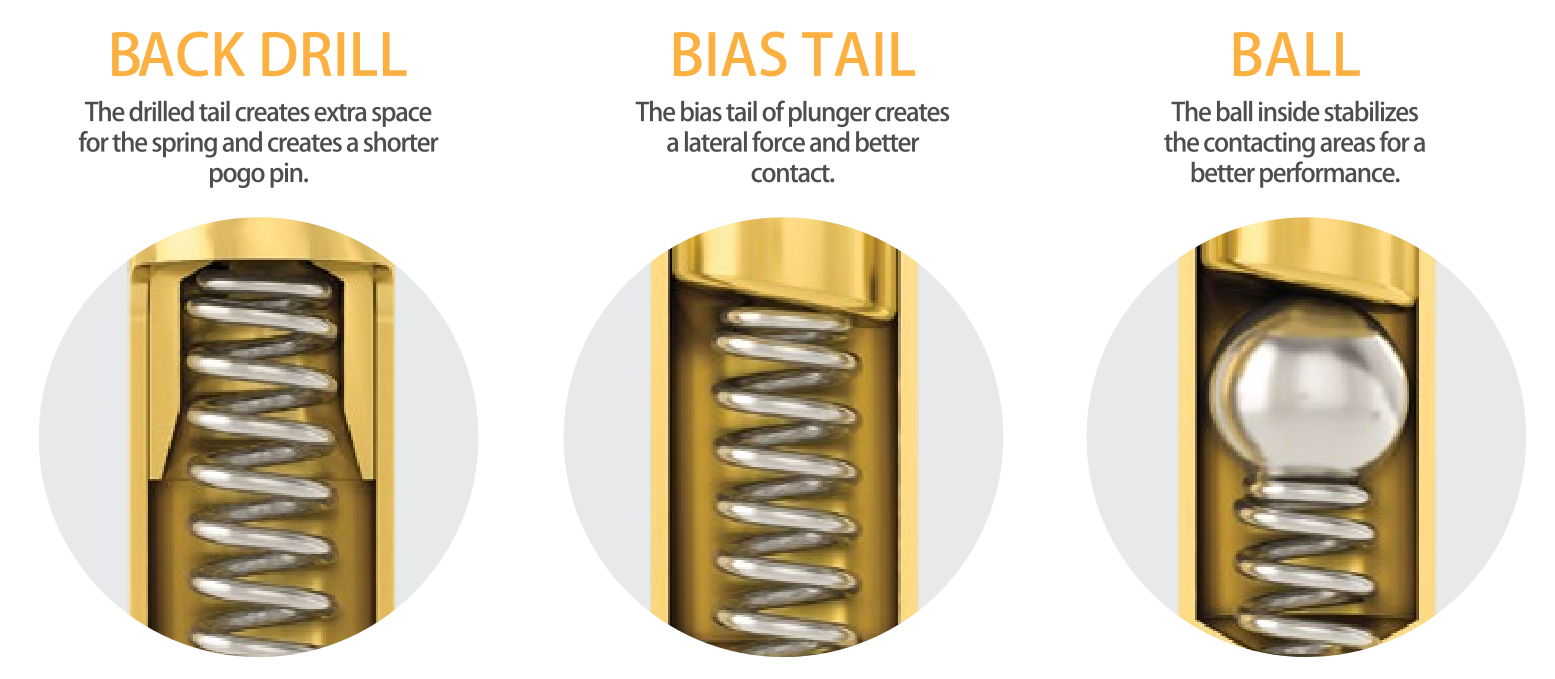

Its structure is intricate, primarily consisting of three core components: the pin (plunger), the tube (barrel), and the spring.

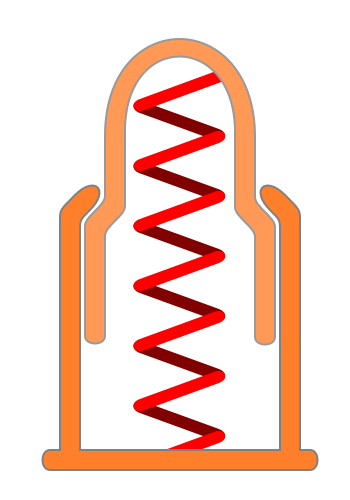

When the earphones are placed in the charging case, the Pogo pin gets to work, allowing current to flow smoothly from the case to the earphones, replenishing their energy.

Behind the “wireless” facade of TWS earphones, every precise connection between the charging case and the earbuds relies on an “invisible core” with a diameter of only 1-3 millimeters—the Pogo Pin.

This micro-component is not just a channel for electrical current; it is a key factor determining the charging stability, durability, and overall user experience of the earphones.

This article will delve into the materials, electroplating processes, and innovative applications to reveal how Pogo Pins support the technical foundation of TWS earphones with “millimeter-level” precision.

Material Analysis: Brass as the Mainstay, with Alternatives for Special Cases

The pin and tube of a Pogo pin are typically manufactured from brass.

This is because brass possesses excellent electrical conductivity and machinability, meeting the current transmission needs of TWS earphones while being easy to process into various precise shapes.

In some scenarios with special performance requirements, stainless steel may also be used to manufacture the pin and tube.

As for the spring component, stainless steel is often chosen for its elasticity and durability.

However, while brass is good, it has a “small drawback.”

Copper is a non-ferrous metal with relatively active chemical properties.

Once exposed to air, it easily reacts with oxygen, and the surface will gradually oxidize.

This is not good news for a Pogo pin, which must maintain excellent conductivity at all times.

Therefore, to solve this problem, the crucial process of surface electroplating is introduced.

Surface Electroplating: Giving the Pogo Pin a “Protective Coat”

To enhance the performance and lifespan of a Pogo pin, surface electroplating is essential.

Through electroplating, the Pogo pin’s surface is covered with a special metal layer.

This layer acts like a “protective coat,” not only effectively preventing corrosion but also improving electrical performance and enhancing stability.

The common plating methods and materials are diverse, each with its own merits.

1. Gold Plating: A Noble and Practical Choice

Among the many electroplating materials, gold plating holds a significant share in the Pogo pin field.

Gold is extremely stable chemically, resistant to oxidation, and has superb corrosion resistance.

This allows gold-plated Pogo pins to withstand a high number of insertion and removal cycles, maintaining excellent conductivity even with frequent use.

For Pogo pin connectors that demand extremely high reliability, transmit micro-signals, and have low contact force, gold plating is undoubtedly the ideal choice.

However, gold is relatively expensive, which also increases the cost of Pogo pins using this process.

2. Nickel Plating: A Cost-Effective Option, But with Caveats

Nickel is often used as a base layer (underplate) during gold plating.

In steel contacts, nickel plating is also widely used (though steel must be copper-plated before nickel plating).

Nickel-plated Pogo pins offer a cost advantage, but they also have some shortcomings.

Nickel is relatively soft, and if used in a high-cycle application, it can be prone to wear.

Furthermore, nickel can also oxidize when exposed to air for extended periods, which may affect contact performance.

3. Silver Plating: High Conductivity but with Shortcomings

Silver-plated Pogo pins have outstanding electrical conductivity and are less expensive than gold.

However, like copper, silver is an active metal and easily oxidizes in the air.

This characteristic limits the application range of silver-plated Pogo pins.

It is generally only selected in special cases that require extremely high conductivity and have special protective measures, making it relatively rare in practical applications.

4. Special Plating (Rhodium, Ruthenium, etc.): Addressing Special Requirements

In addition to the common platings mentioned above, special composite plating processes, such as rhodium-ruthenium, are used in specific scenarios.

These are for when TWS earphones need stronger resistance to artificial sweat, electrolysis, or pool chlorine.

These special coatings can effectively prevent the Pogo pin from sulfidation and oxidative corrosion in complex environments, greatly enhancing the product’s wear resistance and durability, and ensuring the TWS earphones operate stably under various harsh conditions.

From the careful selection of materials to the ingenious application of surface electroplating, every step in the creation of a TWS earphone’s Pogo pin embodies technological wisdom.

These seemingly inconspicuous components, through continuous optimization of materials and processes, are what guarantee the stable performance and long service life of TWS earphones.

The next time you use your TWS earphones, you might pay a little more attention to this tiny Pogo pin and appreciate the hidden technological charm within it.